What Is The Best Fryer And Oil To Fry With?

Q:Can you send me the specifics to help me determine what type of fryer and oil to make the best Fresh French fries?

Bunge Oil and Frymaster are the sources for this terrific information, please go to their web sites for even more tips on frying, equipment and especially look to them for help on picking a particular oil. Some fresh fry chains use olive oil (Elevation Burger comes to mind) and peanut oil (Five Guys). However, for your best bet, try consulting the oil experts directly as the way to go to become more knowledgeable about which single oil or blends are the perfect fit for your operation considering volume, equipment, type of products fried, etc. Here is an abbreviated version of their tips:

Two Key Factors for Fit Frying

Factor 1: Choosing the Right Fryer

The first step in The Five Factors for Fit Frying program is to find the right fryer for the foods you serve. This not only helps produce higher-quality and more healthful foods, but also extends oil life. To find the perfect fryer for your operation, evaluate your menu to determine which fryer is best suited for your needs. The right fryer is the one that is designed to cook the foods you offer on your menu. The Idaho Potato Commission recommends you have a dedicated fryer for potatoes to insure efficiency, recovery time consistency and minimization of off flavors from other foods.

From Frymaster:

In the broadest sense there are two categories of fryers—those with sediment zones and those without. Sediment zones optimize the fry cycle by allowing particles from the food to precipitate away from the cooking area into a location at the bottom of the fryer called “the cold zone.” Different types of fryers offer different “cold zone” collection options.

Open-pot fryers have the heat transfer system outside the fry pot and deep internal sediment collection zones. They perform well in many frying applications, but are ideal for light to medium sediment foods such as French fries and freezer to fryer foods. They can also handle heavier sediment foods with regular filtration. This type of fryer allows every inch of the fry pot to be easily accessed and safely cleaned. Open-pot fryers are available in both gas and electric models.

Open-pot fryers have the heat transfer system outside the fry pot and deep internal sediment collection zones. They perform well in many frying applications, but are ideal for light to medium sediment foods such as French fries and freezer to fryer foods. They can also handle heavier sediment foods with regular filtration. This type of fryer allows every inch of the fry pot to be easily accessed and safely cleaned. Open-pot fryers are available in both gas and electric models.

Tube-type fryers have the heat exchange system inside the fry pot and wide sediment collections zones below the heat exchange tubes, making them the best choice for foods that are fresh battered or heavily breaded such as homemade onion rings or dry dredge fish. Tube-type fryers are available in large capacity models making them the perfect choice for foods that require a large surface area or operations that have high capacity production needs. Tube–type fryers are only available in gas models.

Tube-type fryers have the heat exchange system inside the fry pot and wide sediment collections zones below the heat exchange tubes, making them the best choice for foods that are fresh battered or heavily breaded such as homemade onion rings or dry dredge fish. Tube-type fryers are available in large capacity models making them the perfect choice for foods that require a large surface area or operations that have high capacity production needs. Tube–type fryers are only available in gas models.

Flat-bottom fryers have large frying areas and no sediment collection zones making this type of fryer best suited for food items that float on top of the oil during the fry cycle. Good applications for this fryer are tempura and wet battered fish.

Flat-bottom fryers have large frying areas and no sediment collection zones making this type of fryer best suited for food items that float on top of the oil during the fry cycle. Good applications for this fryer are tempura and wet battered fish.

Factor 2: Select the Right Oil

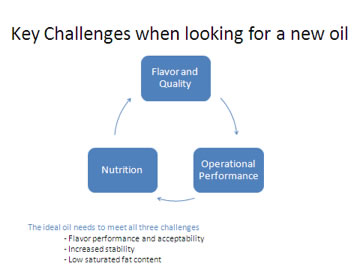

Once you’ve selected the right fryer for your cooking needs, the next step in the Five Factors for FitFrying is to find the right oil. Much attention and study has been given to oil in recent years—its composition, how it impacts the frying process, which type(s) work best with certain foods and ways to extend its life cycle.

From Bunge Oil:

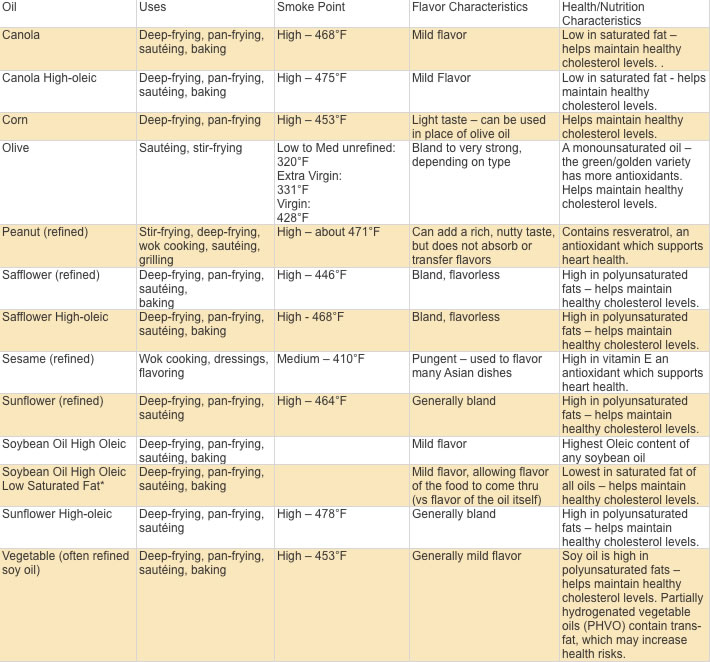

The qualities of your frying oil impact both oil functionality and food quality. Base oils for deep-frying include soy, canola, corn, grape seed, peanut, safflower, sunflower, blends and more. Each type of oil has unique characteristics such as flavor, smoke point, nutritional profile and stability.

Prime considerations for foodservice oils used in deep fat frying, pan frying and griddle frying include sensory attributes, fry life, cost, availability and nutritional considerations. Consider the features and benefits of the different base oils as they relate to your cooking application to select the best oil for your restaurant application.

Historically, frying oil stability was achieved primarily through partial hydrogenation, an artificial process in which hydrogen is applied to the processing of frying oil. This process often creates artificial trans-fat and/or increased saturated fat which are commonly associated with increased health risks, such as heart disease.

Given recent food labeling, nutritional and menu legislation movements and policy changes, the food industry is seeking vegetable oils that not only have enhanced functionality but minimize levels of trans- and saturated fat.

In light of these changes, a new generation of oils has been introduced in the marketplace. Advanced plant breeding technologies have helped create oils that provide enhanced stability and functionality for deep frying, while meeting healthy oil requirements and often improving the mono- and polyunsaturated fatty acid (“good” fats) content and removing partial hydrogenation from the label.

In addition, these enhanced oils also provide your operation with greater stability and functionality needed for deep frying. Greater stability and functionality allow you to have a longer fry life and more versatile oil, creating savings in your restaurant’s bottom line.

Examples of new generation oils include high-oleic, mid-oleic and low-linolenic varieties. Oil manufacturers also offer blends, providing a wider variety of unique flavor profiles and performance.

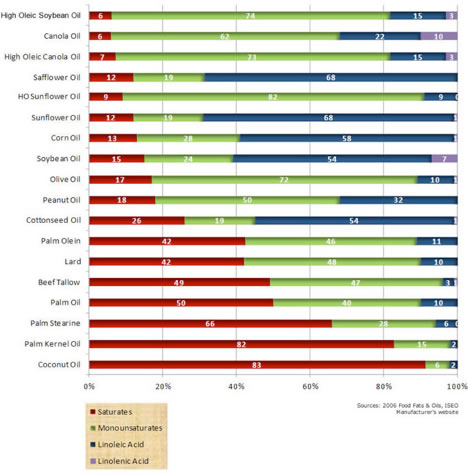

From a saturated fat content, the following chart illustrates how the various oils stack up:

Selecting trans-fat-free food for frying, frying in healthful oil, and following frying best practices will ensure you are consistently providing your customers with high-quality fried foods that are both flavorful and healthy.